Boost company performance through industry "best practices"

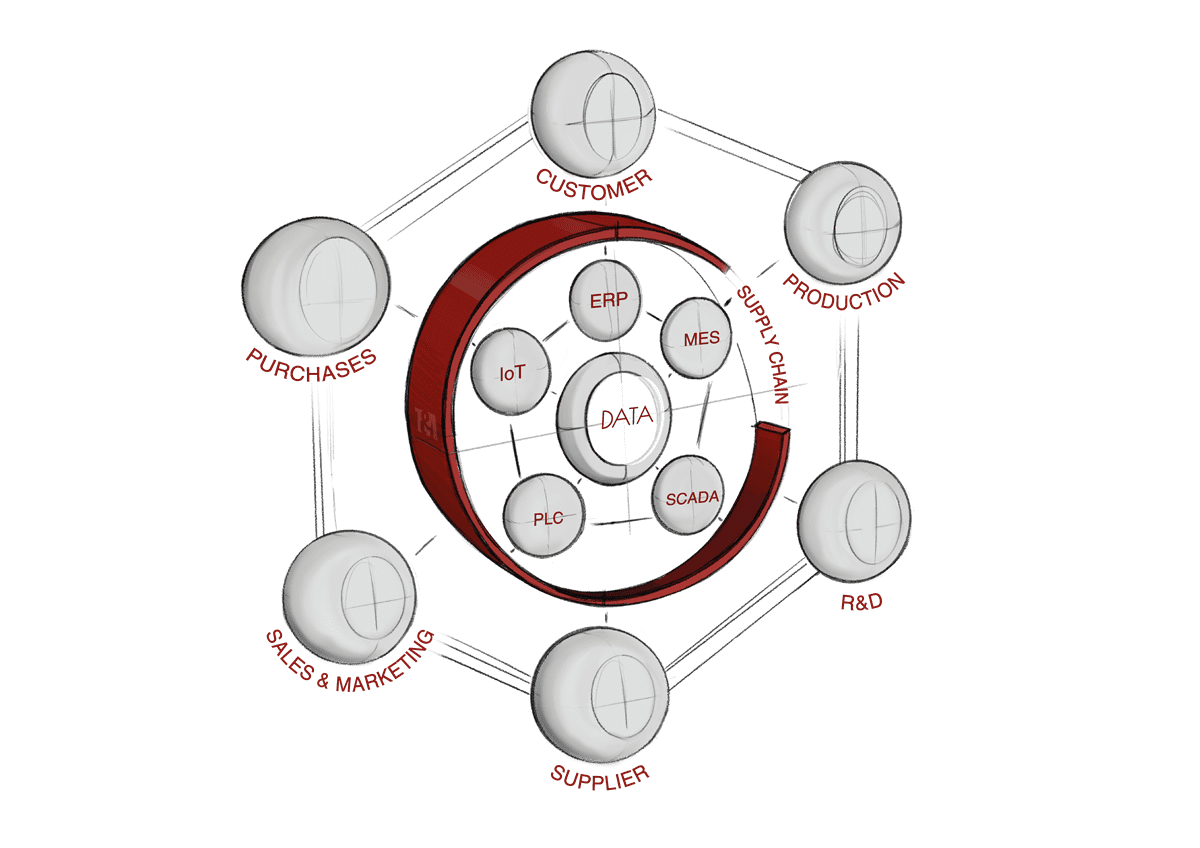

HOW TO DRASTICALLY INCREASE OVERALL PERFORMANCE OF MY SME?

EFFICIENCY & COMPETITIVENESS

ARE THE 2 KEY-DRIVERS OF THE PERFORMANCE

WHICH LEVER SHOULD BE USED TO INCREASE OVERALL PERFORMANCE?

industry 4.0

Transforms the EFFICIENCY and COMPETITIVENESS of the company as a whole.

LEAN MANAGEMENT 4.0

Transforms EFFICIENCY at all levels of the company.

LEAN MANUFACTURING

Stabilizes the VARIABILITY of the production mean.

EFFICIENCy + COMPeTITIVENESS = +60%

COMBINING IMPROVED EFFICIENCY AND COMPETITIVENESS CAN LEAD THE COMPANY TO INCREASE ITS OVERALL PERFORMANCE BY MORE THAN 60%

EFFICIENCY +30%

Improving EFFICIENCY through Kaizen and LEAN MANAGEMENT 4.0 can increase business performance by at least 30%.

COMPETITIVENESS +30%

Improving COMPETITIVENESS through Innovation, Transformation and INDUSTRY 4.0 can increase business performance by at least 30%.

WHAT ARE THE FUNDAMENTALS OF INNOVATION AND TRANSFORMATION?

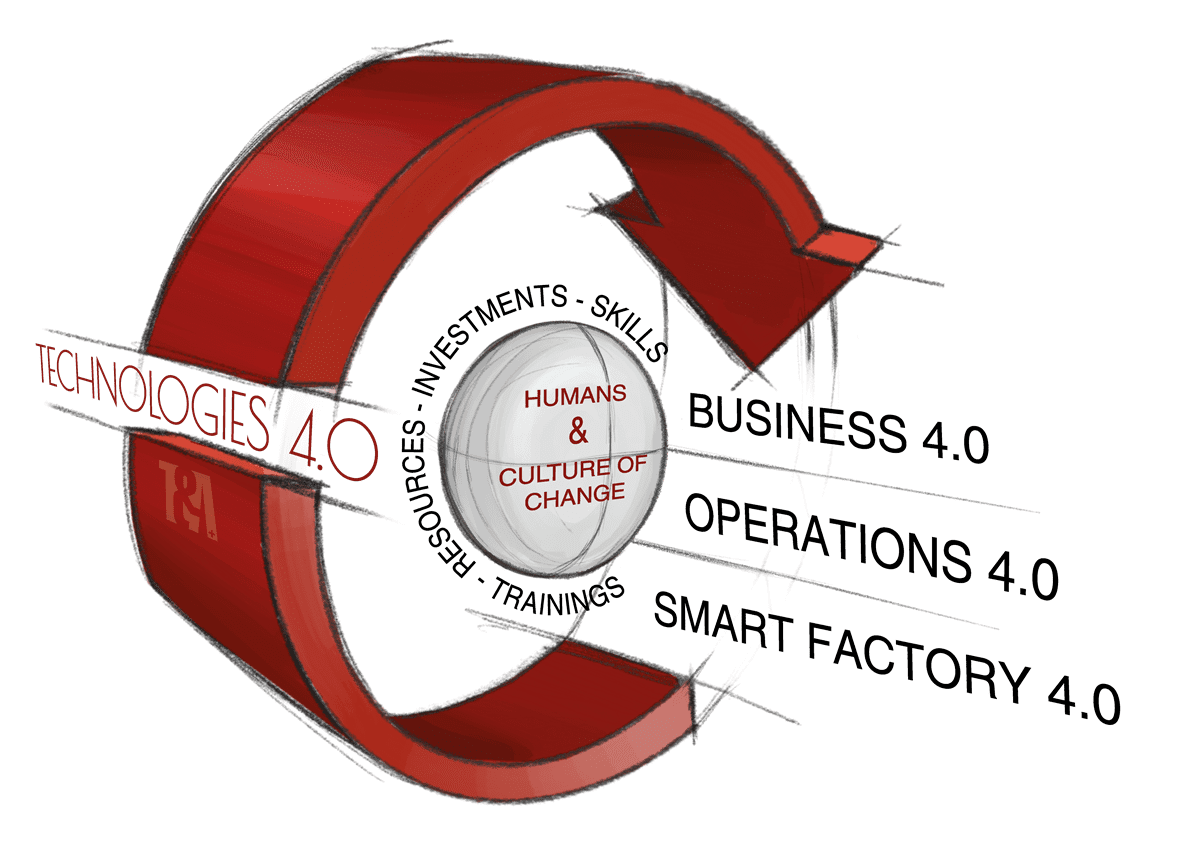

SMART ENTERPRISE 4.0

Today more than ever, a company that wants to be successful and develop its business over the long term must, on the one hand, in an increasingly global, complex, competitive and technological market, fully control its EFFICIENCY and its COMPETITIVENESS in order to aim for OPERATIONAL EXCELLENCE, and on the other hand, to make Innovation a decisive advantage towards its competitors and customers.

The road that leads to Innovation through Agility and Transformation in order to design a SMART ENTERPRISE 4.0, is above all the development and implementation of a series of HUMAN-led company projects that must benefit from a CULTURE OF CHANGE deeply rooted within their organization. Without such a culture, nothing will be possible!

TECHNOLOGIES 4.0

DATA ANALYTICS &

ARTIFICIAL INTELLIGENCE

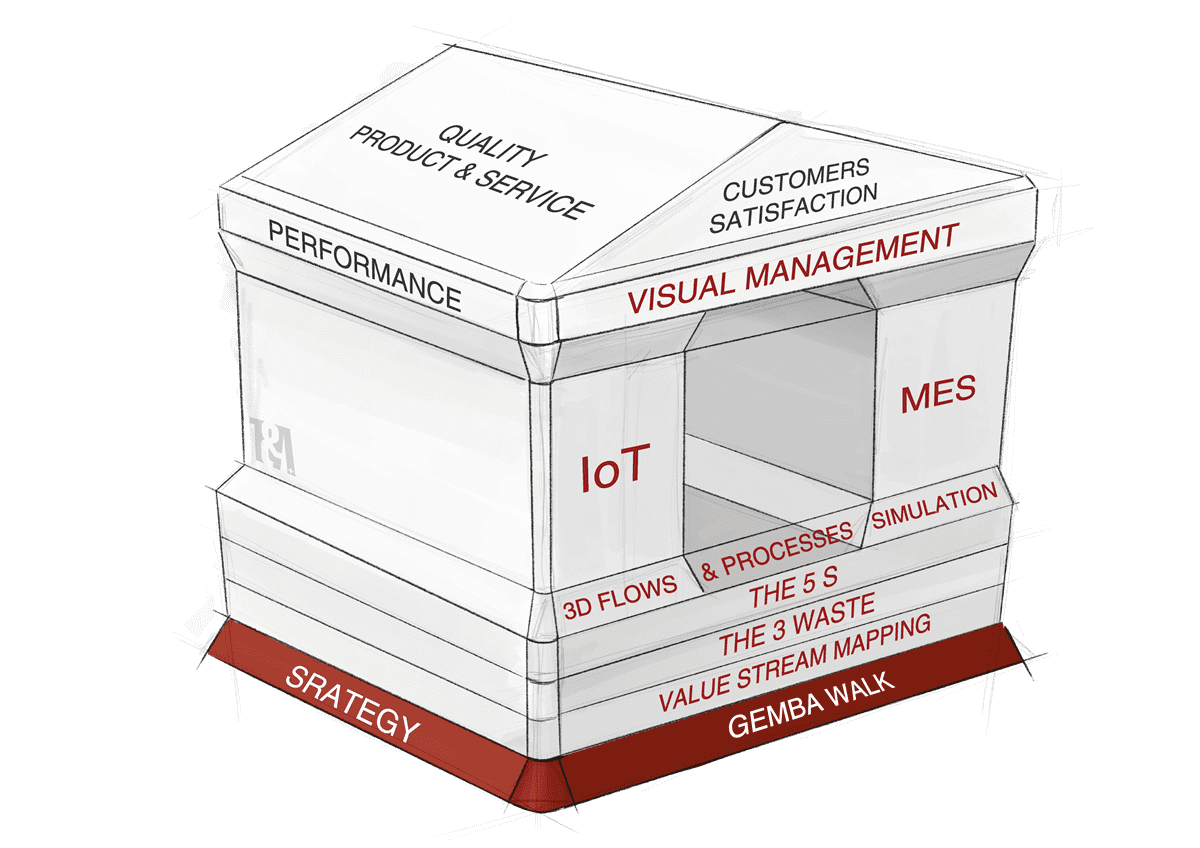

New Technologies 4.0 are the components without which nothing would be possible in terms of Innovation and Transformation. They are numerous, but 2 of them are emerging: DATA ANALYTICS or BIG DATA and ARTIFICIAL INTELLIGENCE or AI. Other technologies such as machine learning or ML, deep learning or DL, Internet of things or IoT, virtual reality or VR, augmented reality or AR, cloud or cloud, physical and software robotics as well as automation also play a vital role. These new technologies will make it possible to carry out fundamental or even radical changes and transformations affecting the company as a whole, further merging the external and internal environments, in particular the 3 layers that are :

- BUSINESS

- OPERATIONS

- SMART FACTORY

BUSINESS 4.0

STRATEGY & BUSINESS MODEL

CRM - CUSTOMER RELATIONSHIP MANAGEMENT

Be or become the leader in its market, be different from its competitors from a technological point of view, stand out vis-à-vis its customers through the functioning of its organization in order to ensure the growth of its business in a world where everything is accelerating, is a huge challenge. IT systems such as CRM or Customer Relationship Management, thanks to Artificial Intelligence, are in the process of radically disrupting the way of interacting between customers and their suppliers. Thanks to connected systems that are becoming more and more intelligent, never in the history of mankind, technologies have been so efficient. They offer businesses unparalleled opportunities to develop new STRATEGIES and new BUSINESS MODELS.

OPERATIONS 4.0

SCM - SUPPLY CHAIN MANAGEMENT

Faster, even faster, always faster ... ever more complex supply circuits, ever more demanding logistics flows, increasingly distant distribution circuits, increasingly short product availability will make that the organizations, structures and infrastructures of companies will have to move from a static hierarchical model to a dynamic systemic model. The way to operate between employees and the way to operate companies require new operational models, especially at the level of SUPPLY CHAIN MANAGEMENT - SCM.

PRODUCTION 4.0

SMART FACTORY 4.0

PLM - PRODUCT LIFE MANAGEMENT

The way in which companies have designed, developed and manufactured products until now is about to be completely turned upside down thanks to new 4.0 technologies and thanks to the concept of PRODUCT LIFE MANAGEMENT or PLM. Imagine a fully intelligent, connected and automated production unit or SMART FACTORY 4.0 whose systems are in constant contact with the product it manufactures thanks to AI and data exchange. Such an advance allows, from design to delivery, to know and trace, continuously; the state, location and lifecycle of the product - PLM within the company or in its environment of use at the customer.

COMPETENCES 4.0

SKILLS & TRAINING

Lean Management 4.0 and Industry 4.0 are new industrial concepts which require new professions and consequently new SKILLS in order to develop new COMPETENCES. It is therefore essential that companies anticipate their needs, in terms of education/training their employees, if they intend to remain competitive and attractive on the employment market. Young engineers from higher education institutions are, by definition, only attracted to companies that have an innovation and change culture.

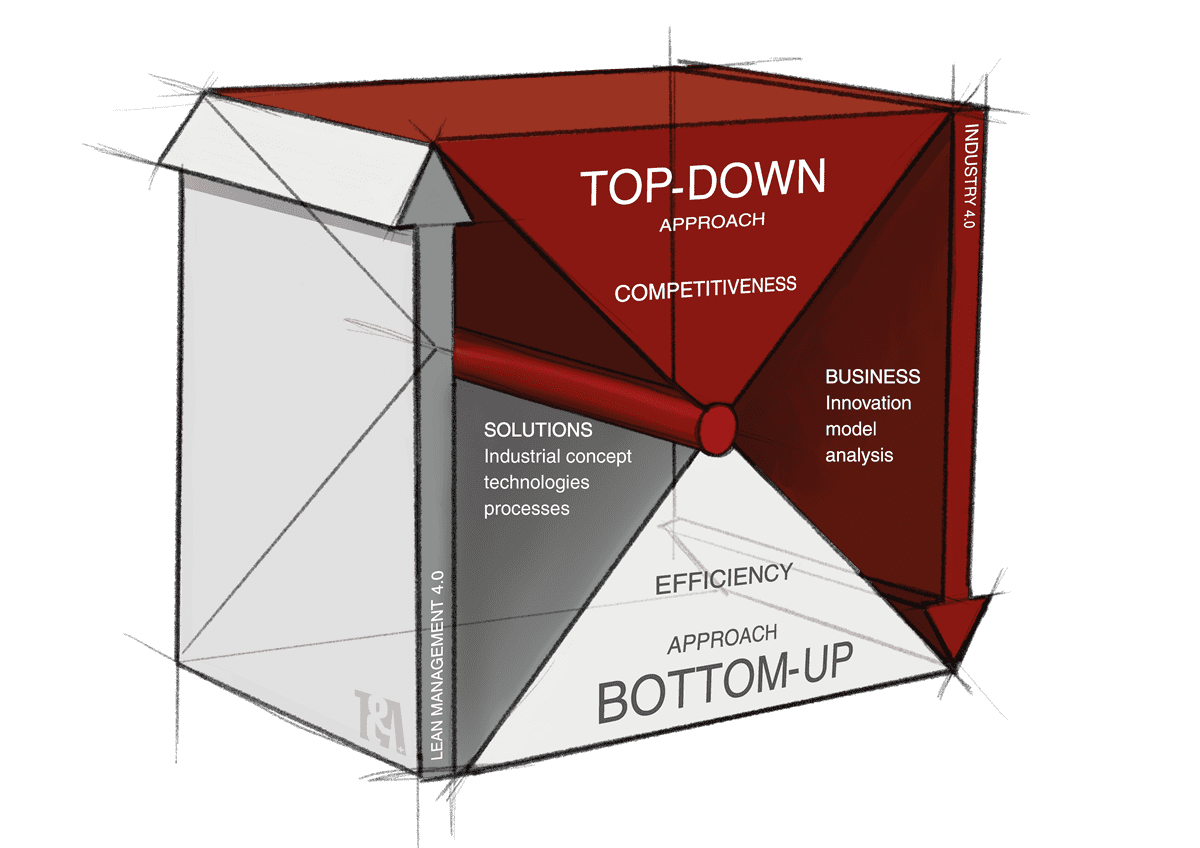

WHAT IS THE STRATEGIC APPROACH TO ACHIEVE THE PERFORMANCE?

BOTTOM-UP vs TOP-DOWN

2 COMPLEMENTARY APPROACHES

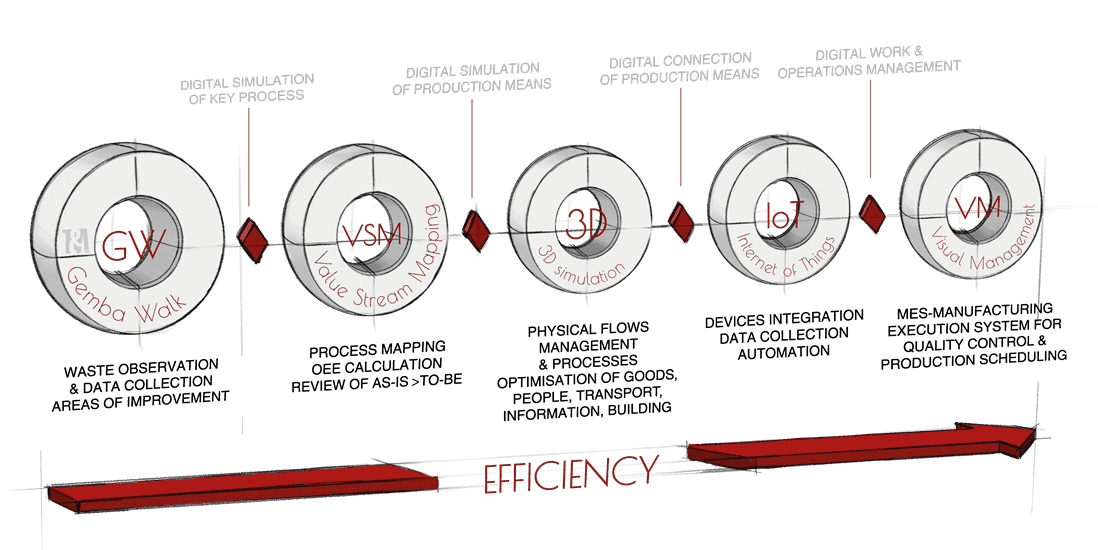

BOTTOM-UP APPROACH

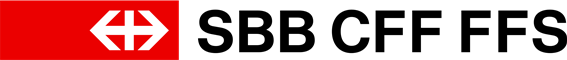

GW -- VSM -- 3D -- IoT -- VM

SOLUTIONS & TECHNOLOGIES

The BOTTOM-UP approach is a LEAN MANAGEMENT 4.0 way called CONVENTIONAL, in 5 phases, oriented towards solutions and technologies.

It wants to be very pragmatic in the sense that the company immediately sets up TECHNOLOGICAL SOLUTIONS thanks to the application of the methodology of LEAN MANAGEMENT 4.0 and certain components of INDUSTRY 4.0. Each of the 5 steps substantially increases the performance of the production mean.

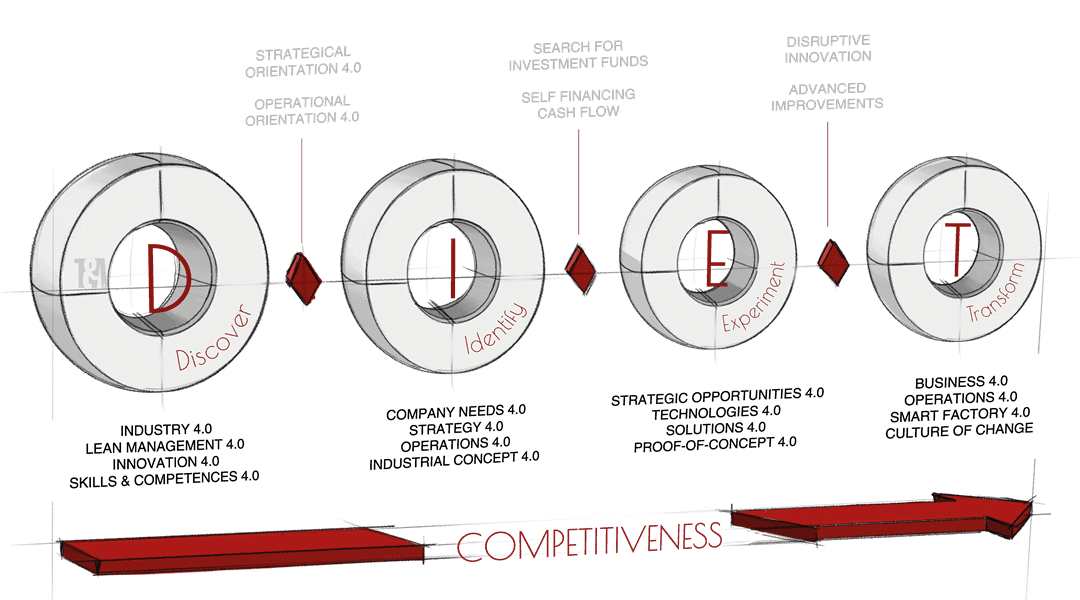

TOP-DOWN APPROACH

D -- I -- E -- T

INNOVATION & BUSINESS

The TOP-DOWN approach is a way towards INDUSTRY 4.0, known as DISRUPTIVE, in 4 phases, oriented towards business, innovation and transformation.

It makes it possible to acquire competences, develop skills, identify NEEDS, define the company's STRATEGY and set STRATEGIC OBJECTIVES in the short, medium and long term in order to define a new 4.0 industrial concept before any velocity, implementation of technologies, innovation or transformation.

OUR SERVICES & SOLUTIONS OFFER

WE SUPPORT SMEs, END-TO-END, DURING THEIR INDUSTRIAL TRANSFORMATION 4.0

- Practical experimentation fot Industry 4.0

- Practical experimentations for Lean Office

- Practical experimentations for Lean Management 4.0

- VSM | Value Stream Mapping

- 3D Simulation - Physical flows

- IoT | Internet of Things

- VM | Visual Management | MES 4.0

- DATA | Collection, Processing, Analysis

- Industry 4.0

OUR REFERENCES